1. Grounding protection of charging piles

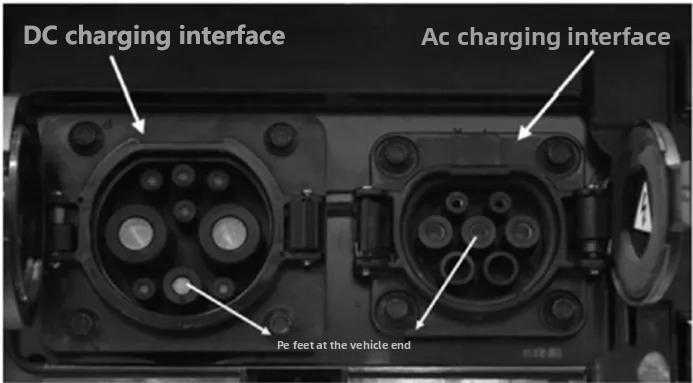

EV Charging stations are divided into two types: AC charging piles and DC charging piles. AC charging piles provide 220V AC power, which is converted into high-voltage DC power by the on-board charger to charge the power battery. DC charging piles provide 380V three-phase AC power, which directly charges the battery through the fast charging port without going through the on-board charger. The national standard GB/T20234.1 clearly stipulates the requirements for vehicle interfaces and power supply interfaces. AC EV chargers use the national standard seven-pin interface, while DC chargers use the national standard nine-pin interface. The PE pins of the two charging interfaces located on the vehicle side are both grounding terminals (see Figure 1). The function of the ground wire PE is to reliably ground the electric vehicle body through the AC electric car charging station. In the national standard GB/T 18487.1, the ground wire PE of the power supply equipment must be connected to the electric vehicle body ground (PE pin in Figure 1) for the electric vehicle’s charging mode to function normally.

Figure 1. PE Pin of Vehicle-Side Charging Interface

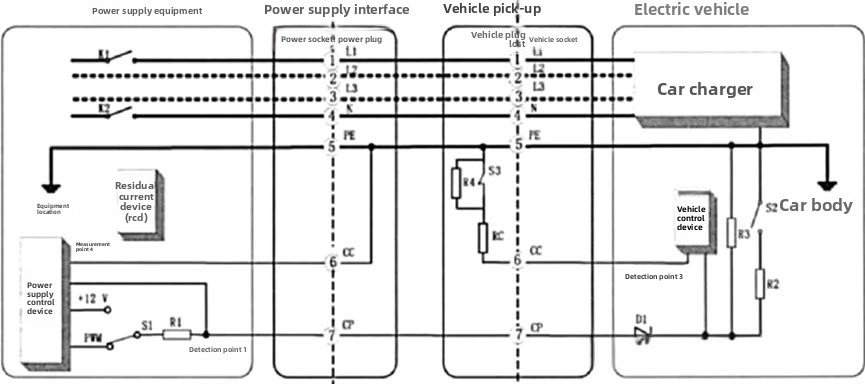

Taking the charging method where an AC electric vehicle charging station uses a two-way plug vehicle connector to connect to the electric vehicle’s charging port as an example, the control circuit of this charging system is analyzed, and its circuit diagram is shown in Figure 2.

When the power supply equipment is set to charge, if the equipment is fault-free, the voltage at detection point 1 should be 12V.

When the operator holds the charging gun and presses the mechanical lock, S3 closes, but the vehicle interface is not fully connected, the voltage at detection point 1 is 9V.

When the charging gun is fully connected to the vehicle’s charging port, S2 closes. At this time, the voltage at detection point 1 drops rapidly. The power supply equipment confirms the signal via the CC connection and detects the current that the charging cable can withstand, switching switch S1 from the 12V end to the PWM end.

When the voltage at detection point 1 drops to 6V, switches K1 and K2 of the power supply equipment close to output current, thus completing the power supply circuit. After the electric vehicle and the power supply equipment establish an electrical connection, the vehicle control device determines the maximum power supply capacity of the power supply equipment by judging the duty cycle of the PWM signal at detection point 2. For example, for a 16A charging pile, the duty cycle is 73.4%, therefore the voltage at the CP end fluctuates between 6V and -12V, while the voltage at the CC end… The terminal voltage drops from 4.9V (connected state) to 1.4V (charging state).

Once the vehicle control unit determines that the charging connection is fully connected (i.e., S3 and S2 are closed) and completes the setting of the on-board charger’s maximum allowable input current (S1 switches to the PWM terminal, K1 and K2 are closed), the on-board charger begins charging the electric vehicle.

During this process, if the PE ground wire is disconnected, there will be no voltage change at the detection point, the power supply circuit cannot be conducted, and an electrical connection cannot be established between the electric vehicle and the power supply equipment. In this case, the on-board charger will be in a power-off state.

2. Grounding disconnection test of the charging system

If the grounding of an AC charging pile’s charging system malfunctions, the power supply equipment will leak current, potentially leading to electric shock and personal injury. Therefore, testing and inspecting charging piles is essential. According to standards such as GB/T20324, GB/T 18487, and NB/T 33008, AC charging pile testing mainly includes general inspections, on-load circuit switching tests, and connection abnormality tests. Using the BAIC EV200 as an example, the impact of abnormal PE grounding on the charging system’s charging status is observed by testing the input and output current changes of the on-board charger.

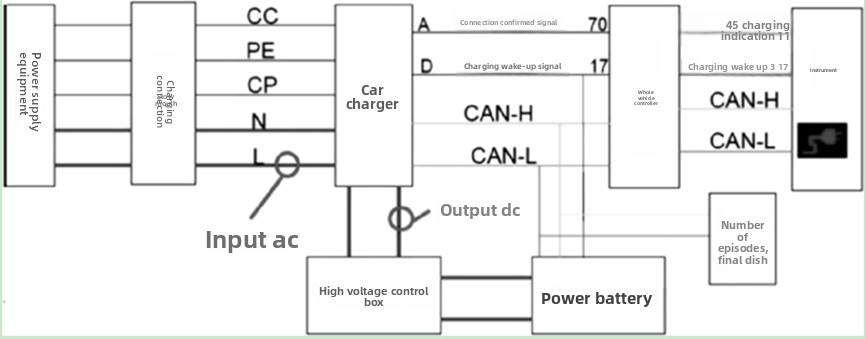

In the system shown in Figure 3, the CC and CP terminals on the left side of the on-board charger are charging control signal lines; PE is the ground wire; and L and N are 220V AC input terminals.

The terminals on the right side of the on-board charger diagram are low-voltage communication terminals. Their main function is to feed back the on-board charger signal to the VCU connection confirmation line, activate the charging wake-up signal line to wake up the instrument panel displaying the connection status, and for the charger to wake up the VCU and BMS. The VCU then wakes up the instrument panel to start displaying the charging status. The positive and negative main relays inside the power battery are controlled by the BMS to close via commands from the VCU, completing the power battery charging process. The terminal at the bottom of the on-board charger in Figure 3, connected to the high-voltage control box, is the high-voltage DC output terminal.

In the PE grounding fault test, two current clamps were used to simultaneously measure the input and output currents. A PE open-circuit fault was set using a self-made AC power supply. When the PE line was normally grounded, the grounding switch was ON. With the current clamp applied to the L (or N) line, the measured AC input current of the on-board charger was approximately 16A. With the other current clamp applied to the DC output power terminal of the on-board charger, the measured current was approximately 9A.

When the PE grounding wire was disconnected and the grounding switch was OFF, the measured AC input current of the on-board charger was 0A, and the DC output power current was also 0A. Upon re-performing the open-circuit test, both currents instantly returned to 0A. This open-circuit test at the PE terminal demonstrates that when the PE grounding wire is disconnected, there is no current at the input and output terminals of the on-board charger, meaning the on-board charger is not operating and therefore does not output high-voltage electricity to the high-voltage control box, preventing the power battery from charging.

Grounding protection for AC charging piles is essential. Without grounding protection, charging stations can cause electric shock hazards. Due to the self-power-off protection of the charging circuit, a connection cannot be established between the electric vehicle and the power supply equipment, and the on-board charger will not work.

—THE END—

Post time: Dec-02-2025