Charging process analysis

IEC 62196-3 provides various connection and coupling methods between ev charging pile plugs and electric vehicle sockets, along with corresponding descriptions of terminal and material characteristics. In DC charging systems, IEC 61851-1 specifies three operating systems based on different connection methods: system A (AA), system B (BB), and system C (CC-FF, differentiated by maximum output voltage).

China uses the same communication method and requirements as system B. DC fast charging and AC slow charging use separate sockets, and communication between the DC charging station and the vehicle is via CAN serial communication.

European and American standards use system C (FF), short for combined charge system. DC and AC are integrated into a single socket. Communication between the electric vehicle charging station and the vehicle is via PLC (Power Line Carrier), with high-frequency communication messages coupled to the CP and PE lines for transmission. The communication protocol is ISO/IEC 15118 or DIN SPEC 70121.

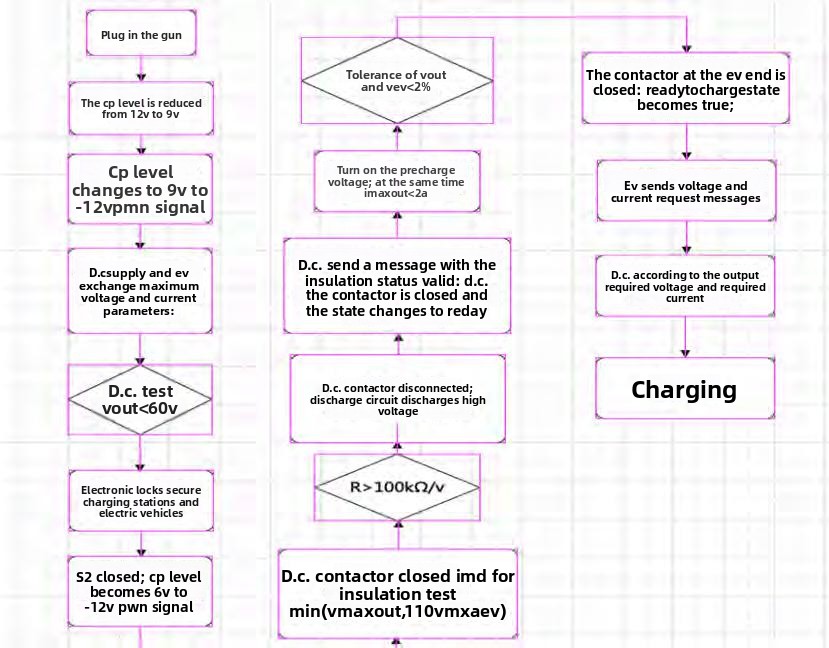

The normal charging process can be divided into four stages: initial connection -> insulation detection & pre-charging -> charging -> end charging. The confirmation and transition of each stage of charging are completed directly or indirectly through the control signal circuit (CP).

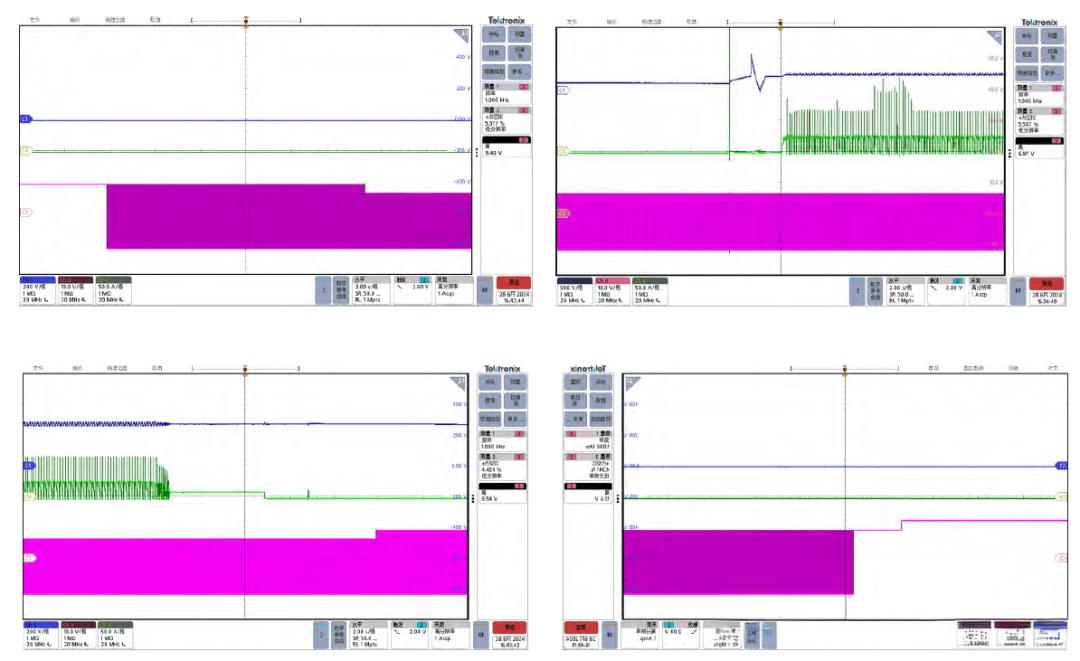

Electric Car Charging Phase

The timing sequence for DC charging is described in detail in Annex CC of IEC 61851-23.

Charging Completion Phase

After charging is complete or the vehicle sends a message requesting to stop charging, the ev charging pile should reduce its output current to below 1A within a specified time. Relay detection and disconnection.

After detecting that the output current has dropped to 1A, the relay will close in two ways:

First:

The relay on the power battery side disconnects first, then the electric vehicle charging pile’s output relay disconnects, and the discharge circuit begins to operate. Subsequently, the vehicle’s S2 switch disconnects, and then the electronic lock disconnects until the charging gun is completely disconnected.

Second:

The ev charging station’s output relay disconnects, the discharge circuit begins to operate, and then the vehicle’s S2 switch disconnects. At this time, the vehicle’s on-board relay is still connected. The relay first closes, then opens, and then closes again, checking if the output voltage matches the battery voltage to determine if the vehicle-side relay is functioning correctly. Then the electronic lock disconnects until the electric car charging gun is completely disconnected.

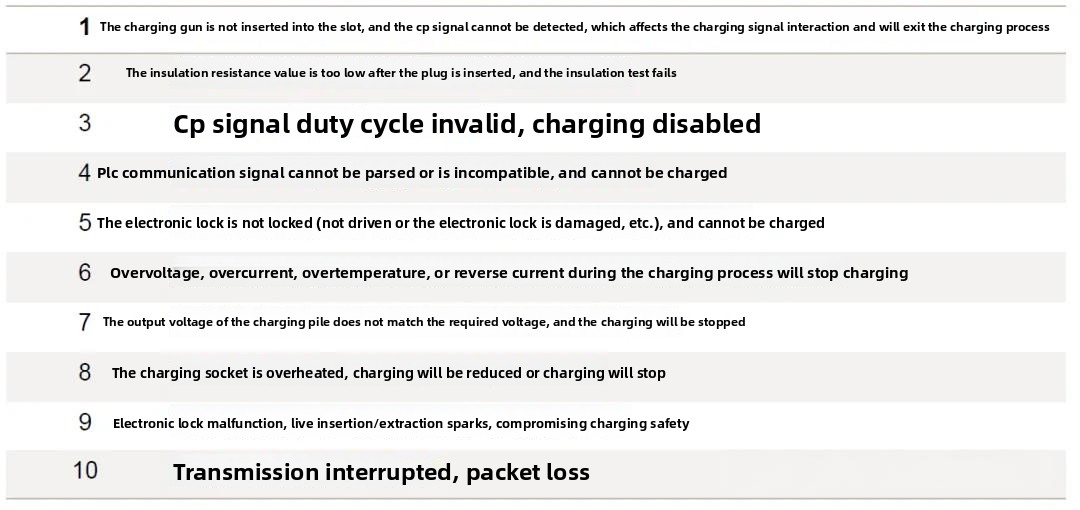

Possible malfunctions during the charging process

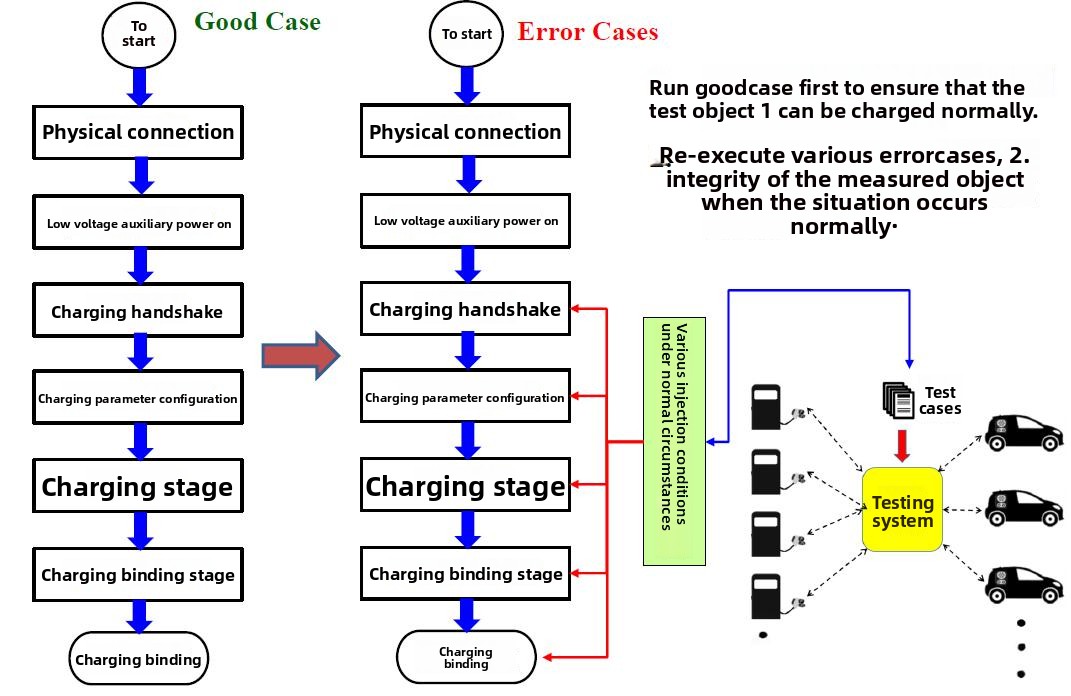

Communication consistency testing (using CCS as an example)

— THE END —

Post time: Dec-26-2025