Upstream equipment: The charging module is the core equipment of the charging pile.

• The charging module is the core component of a DC charging station, accounting for 50% of the equipment cost. From the perspective of working principle and structure, the AC/DC conversion for AC charging of new energy vehicles is achieved inside the vehicle by the onboard charger, making AC charging stations relatively simple and low-cost. However, for DC charging, the AC-to-DC conversion process needs to be completed inside the charging pile, thus requiring the charging module. The charging module affects circuit stability, overall pile performance, and safety. It not only provides energy but also performs AC-DC conversion, DC amplification, and isolation, determining the performance and efficiency of the electric car charging station and possessing a high technical threshold. According to China BEIHAI Power, the gross profit margin of a 30kW charging module reached 35% in 2022.

• The cost of charging modules is showing a downward trend. DC charging modules consist of semiconductor power devices, integrated circuits, magnetic components, PCBs, capacitors, and chassis fans, among other components. With technological advancements, the cost of charging pile modules has been continuously decreasing. According to data from the Charging Alliance, the cost of DC charging pile modules dropped from RMB 1.2/W in 2016 to RMB 0.38/W in 2020.

• The market space for charging modules is positively correlated with the market space for DC charging equipment, while the market space for DC charging piles is closely related to the number of new energy vehicles in operation. Regarding the number of DC charging piles in operation, since DC charging piles are mainly used in the public sector, the number of public DC charging pile is the primary source of the total number of DC charging piles in operation. Overseas market space estimation: The market space is expected to reach RMB 23 billion by 2027, corresponding to a CAGR of 79% over the next 5 years.

Upstream Equipment: Charging Module Development Trends – High Power + Liquid Cooling

• With the trend towards fast charging, charging modules are developing towards higher power. 800V or higher high-voltage platforms are becoming the trend for new energy vehicles, and the high-power supercharging pile industry chain is maturing. High-power charging modules improve the integration of charging systems, thereby reducing the overall cost of charging piles. To achieve high-power charging, the number of charging modules connected in parallel needs to be increased, thus increasing the usage of charging modules. The price per watt of a charging module will decrease as power increases because some components can withstand higher power; the cost of these components can be spread out as power increases, resulting in higher product value and profitability for high-power charging modules. Due to the limited space within charging piles, simply increasing the number of charging modules can no longer meet the power increase requirements of DC charging piles; therefore, increasing the power of individual charging modules is an inevitable trend in the charging module industry.

Charging modules are developing towards higher power

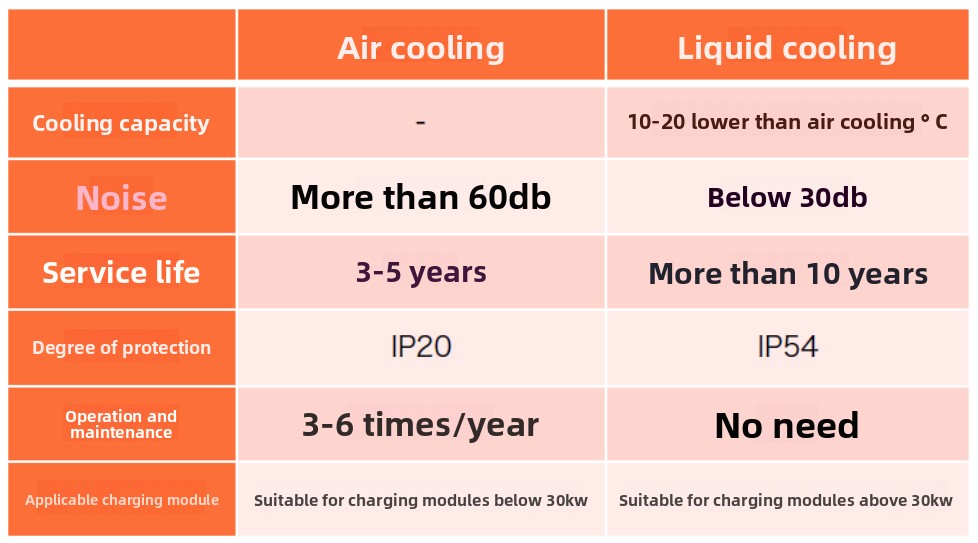

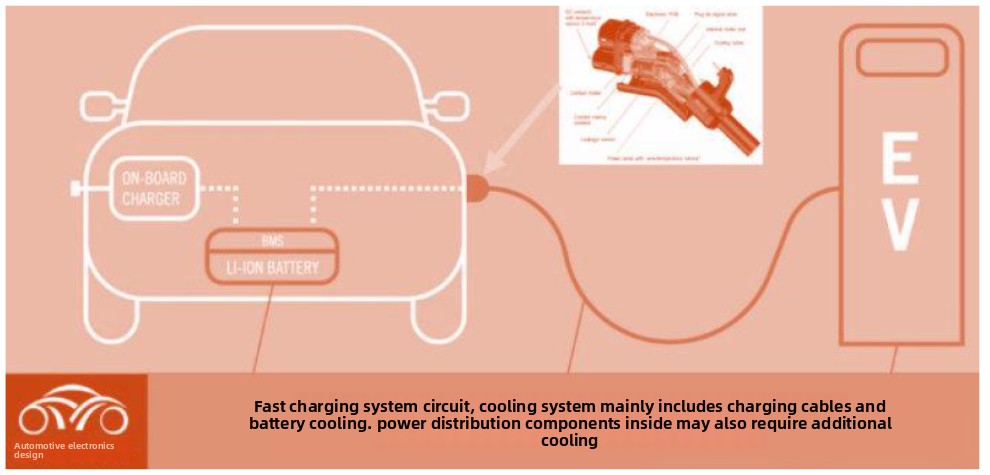

• While moving towards high-power charging, solving the heat dissipation problem becomes crucial. The advantages of liquid cooling will become increasingly prominent, and with further technological development, liquid cooling is expected to become an industry trend. Module cooling methods are shifting from air cooling to liquid cooling. Traditional charging piles use direct air cooling, which reduces module temperature through air heat exchange. However, because internal components are not isolated, in harsh environments, dust, salt spray, and moisture can adhere to the component surfaces, causing module malfunctions. Liquid cooling charging station, on the other hand, employs fully isolated protection technology. The internal components of the charging module exchange heat with a heat sink via coolant, completely isolating them from the external environment, thus offering significantly higher reliability than air cooling. Furthermore, liquid cooling is also applied to charging guns and cables, by adding coolant pipes inside these components. Currently, liquid-cooled charging modules are more expensive, but require less maintenance and repair, reducing operating costs, and are expected to become the mainstream heat dissipation method for charging modules in the future.

Comparison of air cooling and liquid cooling performance

Components used in liquid cooling systems for charging piles: charging modules, charging guns, charging cables, etc.

Post time: Dec-15-2025