This news article discusses the electrical structure of a dual-gun DC charging pile, elucidating the working principles of single-gun and dual-gun electric vehicle charging piles, and proposing an output control strategy for equalization and alternating charging of dual-gun charging station.

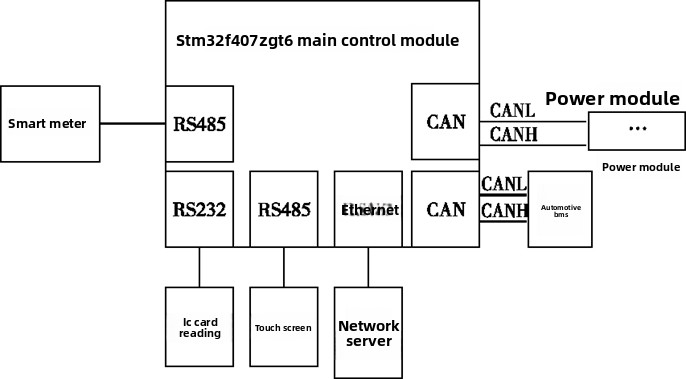

To improve the intelligence and real-time response of charging control, this article also mentions a design scheme for a charging pile control system based on the STM32F407 main control chip with a Cortex M4 core and an embedded FreeRTOS operating system.

Design of the overall electrical topology of charging piles

Architecture Design

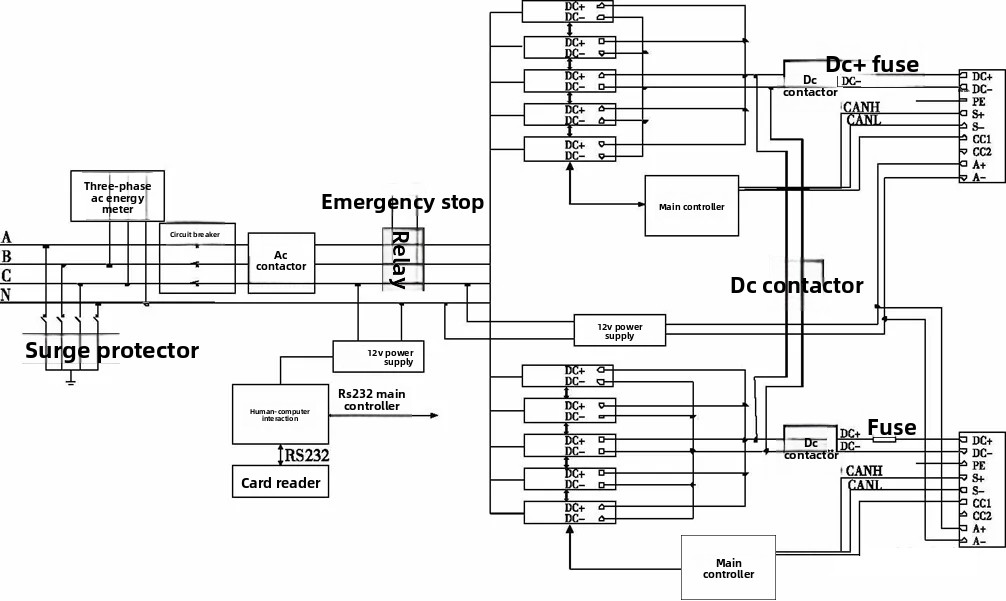

This new presents a design for a dual-gun DC EV charger, consisting of a main controller, power module, human-machine interface display, IC card reader, smart energy meter, AC contactor, DC contactor, circuit breaker, surge protector, and two 12V DC power supplies. The overall electrical diagram of the charging pile is shown below. The electrical connection design between the charging pile and the A and B guns conforms to the national standard for DC charging interfaces of conductive charging devices for electric vehicles.

Working principle

The charging station is a dual-gun DC charging station, employing 10 power modules connected in parallel, designed with two charging control modes: equalization charging and staggered charging.

Equalization charging: Both guns A and B charge simultaneously, with a maximum of 5 power modules charging from each gun.

Staggered charging: When only one gun is operating, a maximum of 10 power modules can charge.

The power modules receive three-phase AC power input, connected to a surge protector, a three-phase AC energy meter, and an AC contactor. The power modules output DC power. An emergency stop button is also included at the input, allowing for emergency stop protection by cutting off the three-phase input. The main controller communicates with the power modules via a CAN bus to exchange output control commands, and the power modules are also connected via a CAN bus. The station has two 12V DC power supplies: one connected to the A+ and A- pins of the charging gun to provide low-voltage auxiliary power to the electric vehicle, and the other powering the human-machine interface display.

Design of main control system

A. System Functional Block Diagram

The main control system block diagram is shown below. The main control chip of the system is STM32F407ZGT6, which has rich peripheral interfaces: 2 CAN, 4 USART, 2 UART, 1 Ethernet interface, etc., which meet the basic interface requirements of the charging pile control system to control peripherals such as power modules, smart meters, IC card readers, and touch screens.

B. Main Control System Hardware Circuit Design

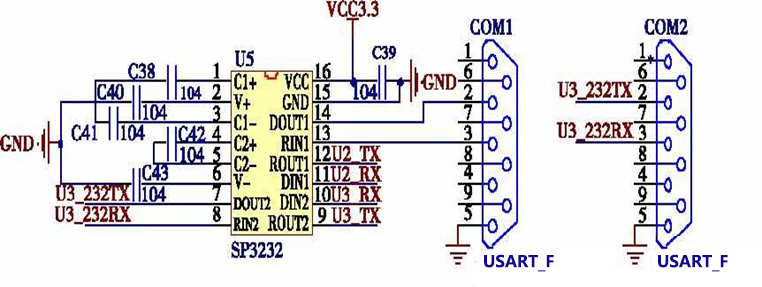

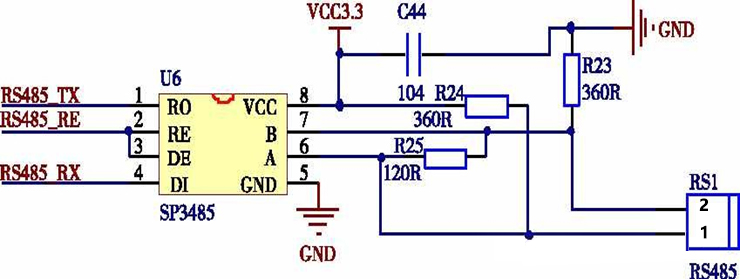

This includes the design of bus interface circuits for RS232, RS485, and CAN.

RS232 Interface Design

RS485 Interface Design

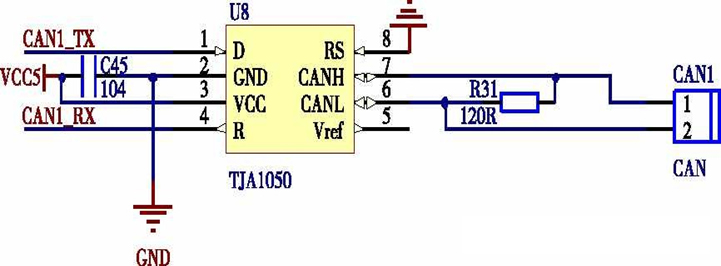

CAN Interface Design

—THE END—

Post time: Dec-01-2025